Product Line

Use the arrow on the left to view documents Use the buttons on the left to view or print PDF documents

Since 1925, Lawrence Roll-Up Doors, Inc. has been manufacturing steel and aluminum rolling door products in Los Angeles, California. We offer various duty-cycle rated doors and grilles to meet the needs and budgets of each building owner or tenant. Our “H-Series” products are suitable for the most demanding conditions of heavy industrial settings, maximum-security environments, and high-frequency usage. Lawrence “M-Series” doors are our most popular products, value engineered for normal commercial applications. Our “S-Series” doors and grilles combine quality design and lighter weight construction to offer an economical product for the most cost conscious buyer. “C-Series” products combine door and grille features with more compact designs for service counters and other small openings. “P-Series” products are designed for 500,000 cycles usage and higher speed applications. “Gateway Series” Doors & Grilles provide controlled egress and secure access for interior openings, storefronts, parking garages, and other commercial applications with patented “Fail-Safe” or “Fail-Secure” automatic opening features. Decades of product design and manufacturing experience enable us to provide Custom Products to comply with special design and unique installation requirements.

Model HD Service Doors are designed for a standard 20,000 cycles usage but can be upgraded to 50,000 or 100,000 cycles, include 22, 20 or 18 gauge galvanized steel flat slat curtain, a 4″ wide T-shape extruded aluminum or rugged double steel angle bottom bar and heavy steel guides. They are available with a large variety of options and can be made up to 40′ wide, 32′ high.

Model MD Service Doors include a 20,000 cycles spring design, can be provided with a 24, 22 or 20 gauge galvanized steel flat slat curtain, heavy extruded aluminum or double steel angle bottom bar, and steel guides. MD service doors are available with most of the same features and options as HD service doors and can be used on openings to 20′ wide and 16′ high.

Model SD Service Doors are suited for applications with up to 10,000 cycles usage, utilize an efficient 24 gauge galvanized steel semi-curved slat curtain, include an extruded aluminum bottom bar, lighter weight steel guides, and can be provided with many options. SD service doors are limited in size to 14′ wide, 14′ high, 200 sq. ft.

Model CD Counter Service Doors combine many of the same features and benefits of full size service doors with a more compact design resulting in an attractive product requiring less clearance suitable for use on smaller openings to 20′ wide, 10′ high, 120 sq. ft. Stainless steel counter tops are also available.

Model PD High Performance Doors with standard or insulated slats are designed to operate for 500,000 cycles with operating speeds of 24 inches per second to open, 12 inches per second to close. They provide longer life as well as enhanced security and environmental control through faster operating speed and less open time.

NOTE: Service doors are available as Weather-Edge Doors (Models HW & MW) with full perimeter weather seals to reduce water and air infiltration, as Insulated Doors (Models HI & MI) for maximum climate control, or as Ventilated Doors (Model HV) with perforated or fenestrated slat curtains for the ultimate combination of ventilation, visibility, and security. Many service door and counter service door products can be provided with stainless steel or aluminum slats, bottom bar, guides and hood.

Model HL Fire Doors combine many HD service door design features – including high cycle operation – with simplified automatic closing and “Easy-Reset” or “Auto-Reset” functions to provide state-of-the-art fire protection for doors in higher usage applications up to 40′ wide, 32′ high.

Model ML Fire Doors provide the functions and features most commonly needed for typical fire doors up to 16′ wide and 16′ high in normal usage applications.

Model SL Fire Doors offer the same closing and reset systems of HL and ML fire doors, but with a lighter weight door design intended for less frequent usage and fire protection of smaller openings to 14′ wide and 14′ high.

Model IL Insulated Fire Doors combine fire protection properties of fire doors with the benefits of thermal insulation and sound control for openings up to 36′ wide and 24′ high.

Model CL Counter Fire Doors provide the same high levels of fire protection and many of the same features as full size fire doors, but in a compact door design for smaller openings up to 16′ wide, 10′ high, 120 sq. ft. Stainless steel sills (labeled counter tops) are also available.

Closing Systems – All “Easy-Reset” and “Auto-Reset” chain, crank and motor operated fire doors close automatically without a loss of spring tension and eliminate the need for traditional mechanical reset.

Fire Door Alarm Releases to interface with alarm systems/detectors and audible/visual warnings prior to closing are also available. Model AR-D is a basic time-delay failsafe release. Model AR-D2 incorporates a battery backup system to support devices connected to it and prevent automatic closing during a loss of building power not related to a fire condition.

Retrofit Fire Door Operators – UL Labeled and FM Approved retrofit fire door operators are available for most types and brands of existing rolling fire doors. When retrofitted with these chain, crank or motor operators, even older fire doors can be tested and reset easily, operating with the same reliability and extraordinary descent control characteristic of our “Easy-Reset” and “Auto-Reset” fire door products.

NOTE: Lawrence fire doors & counter fire doors are classified by Underwriters Laboratories (UL), certified for Canada (c-UL), FM Approved, and listed by the California State Fire Marshal (CSFM). They are approved for installation in non-masonry walls rated up to 3 hours, and in masonry walls rated up to 4 hours. Fire and counter fire doors are available with a supplemental S-Label as air leakage rated Smoke Door assemblies. Most fire doors and counter fire doors can be provided with stainless steel slats, bottom bar, guides and hood.

Model HG Grilles are designed for a standard 20,000 cycles usage – and upgradable to 50,000 or 100,000 cycles – with a durable aluminum straight link pattern curtain, and heavy extruded tubular aluminum bottom bar and guides. A self-leveling bottom bar (up to ½”) and field adjustable curtain stop and lock bar heights are standard features. HG grilles are ideal for larger size openings to 45′ wide, 32′ high and higher usage applications.

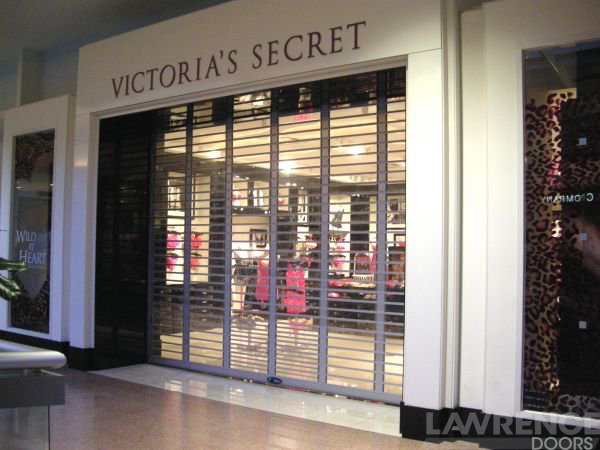

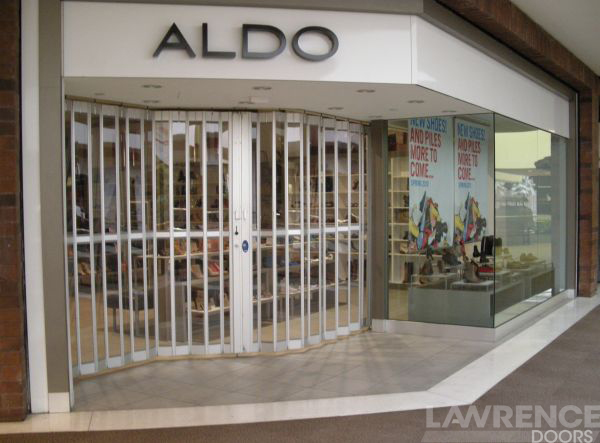

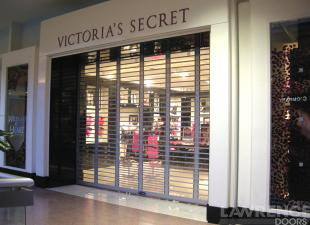

Model SG Grilles are intended for lower usage applications of up to 10,000 cycles for typical storefronts and shopping malls. These grilles offer the same features as HG grilles, but with a lighter weight curtain construction. SG grilles are suitable for openings to 30′ wide, 14′ high, 300 sq. ft.

Model CG Counter Grilles combine the compact design and finished appearance of a counter service door with the ventilation and visibility of a grille. They require minimal clearances and are well suited for service counters and small entry openings to 20′ wide, 8′ high, 100 sq. ft.

Model PG High Performance Grilles are designed to operate for 500,000 cycles with operating speeds of 24 inches per second to open and 12 inches per second to close. They are well suited for parking garages and other applications where traditional roll-up grilles do not adequately meet the demands for very high frequency usage or the desire for higher speed operation. Model PT High Performance Tight-Coil Grilles offer the cycle life and speed of the PG in a patent pending low headroom design that fits into as little as 12″ clearance.

NOTE: Most grille and counter grille products can be provided with a stainless steel curtain and hood.

Rolling & Side-Folding Closures

A-Series Rolling Closures offer grille features combined with the enhanced security of a closed-panel curtain construction. Aluminum panels can be provided with Clear Glazing for visibility, or Solid when visibility is not wanted.

F-Series Side-Folding Closures operate easily, stack compactly and need no headroom. Requiring only a top track for mounting, they can slide straight or through curves. They are available with Open Panels, Glazed Panels, Solid Panels, or traditional Rod-and-Link style grille curtains.

![]()

DC Series Gates are designed for maximum durability and security. Double steel channels, which extend into the top and bottom tracks, are riveted together to form each vertical member. Channels are connected with double rows of steel lattice bars traveling on nylon bearings and washers to operate with a minimum of effort. Leading and trailing edges are steel box shaped sections. DC series gates can be manufactured to almost any size.

EG Series Gates are value engineered to offer a balance between security and economy. Vertical members are single steel channels extending into the top and bottom tracks, alternating with steel flat bars, and connected with single rows of steel lattice bars traveling on formed steel glides for carefree operation. EG series gates are commonly provided up to 30’ wide and 12’ high, but even larger sizes may be available for some models.

LT Series Gates are performance-designed to meet the needs of the most cost-conscious buyer. Quality construction is achieved by the use of diagonal steel lattice channels in a diamond pattern riveted together through plated spacers for smooth operation. LT series gates are normally limited to 26’ wide with a standard height of 6’-6”.

Portable Gates – DC and LT Series gates are also available in fully portable versions on rolling stands for temporary usage in adjustable widths and a typical 6’-6” extended height.

Gate Cabinets can be provided to secure and conceal gates when not in use. Recessed steel cabinets with lockable hinged doors are available in “deep” and “shallow” designs for varying installation conditions.

NOTE: Most gates can be either single sliding or bi-parting, and can roll on floor casters or in top or bottom tracks.

![]()

Chain Gates are fabricated from horizontal and vertical rows of interconnected chain links in a square pattern suspended from a top track. They are typically used as easily operated collapsible sliding enclosures on truck trailers, but can be adapted to provide inexpensive access control for smaller openings on buildings as well.

![]()

Tarps are manufactured from waterproof S400 18 oz. PVC coated nylon with rip-stop mesh reinforcement, or a multi-mesh PVC coated nylon. They are available as either flat or fitted, in a choice of sizes and colors, and can be customized to include “D” rings, straps, vents, and more. Although primary uses are to provide weather protection or containment for hauled loads, they are also well suited for many other applications.

Equipment Covers can be fabricated from the same rugged tarp materials and specially formed to fit many different shapes.

Environmental Curtains made of tarp materials can be provided as sliding or vertical rolling units for a variety of uses such as privacy screens, bug screens or cargo covers on the rear of truck trailers.

Welding Screens maintain visibility of work areas while reducing welding arc glare. They are made from yellow or green transparent vinyl and are available as either fixed-frame or operable models for portable or stationary use.

Specialty Products

Lawrence Doors produces passenger boarding bridge replacement parts for roll-up doors, and cab and rotunda curtains and barrels, used on Jetway, DEW, Ameribridge and other brands.

Lawrence Doors manufactures custom wind turbine nacelle roll-up doors. These uniquely designed products with compound curved tracks roll down to open and utilize a “floating” curtain system to accommodate wind driven motion of the nacelle structure.

Lawrence Roll-Up Doors, Inc. reserves the right to change specifications without notice. Refer to Standard Specifications sheets (available upon request) for complete product information. © 2024 Lawrence Roll-Up Doors, Inc.